Centralizing design at ge to move faster and smarter

Building a centralized design system to reduce design debt, increase design + development speed, and align teams at scale.

Details

Role: Product Designer & Researcher

Platform: Platform & Web

Timeline: 12 weeks

Team: 1 designer, 3 PM, 4 engineers

The Challenge

GE Renewables had multiple teams designing and building across different platforms—but no shared source of truth. Without a unified system, designers duplicated work, developers recreated components inconsistently, and even basic UI decisions varied wildly across teams.

The result? Design debt, slower build times, and mounting inconsistencies across internal tools.

My goal was to create and launch a centralized design system that improved efficiency, alignment, and visual consistency across GE’s product ecosystem.

Discovery & Research

To get started, I needed to answer a big question: how do you build a design system for a large, complex org with fragmented tooling and inconsistent standards?

I began by:

Researching design systems at scale (Medium articles, case studies, DSM documentation)

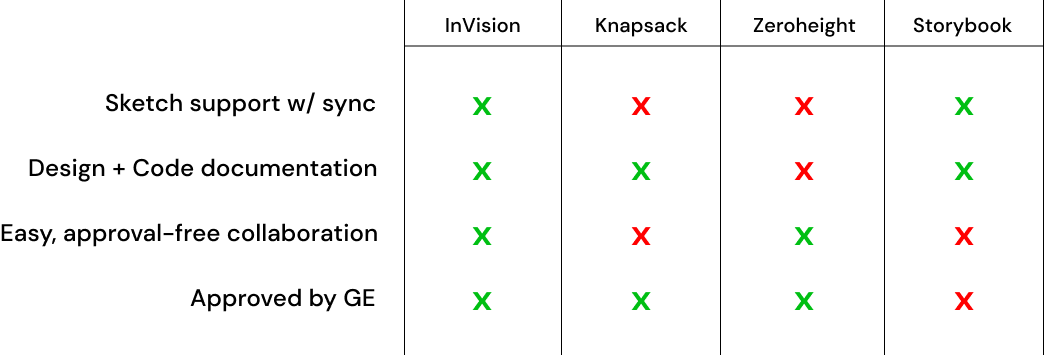

Exploring tools and ultimately selecting InVision DSM, based on its real-time collaboration, Sketch integration, and scalability

Completing an 8-week internal workshop series to learn DSM and align on system goals

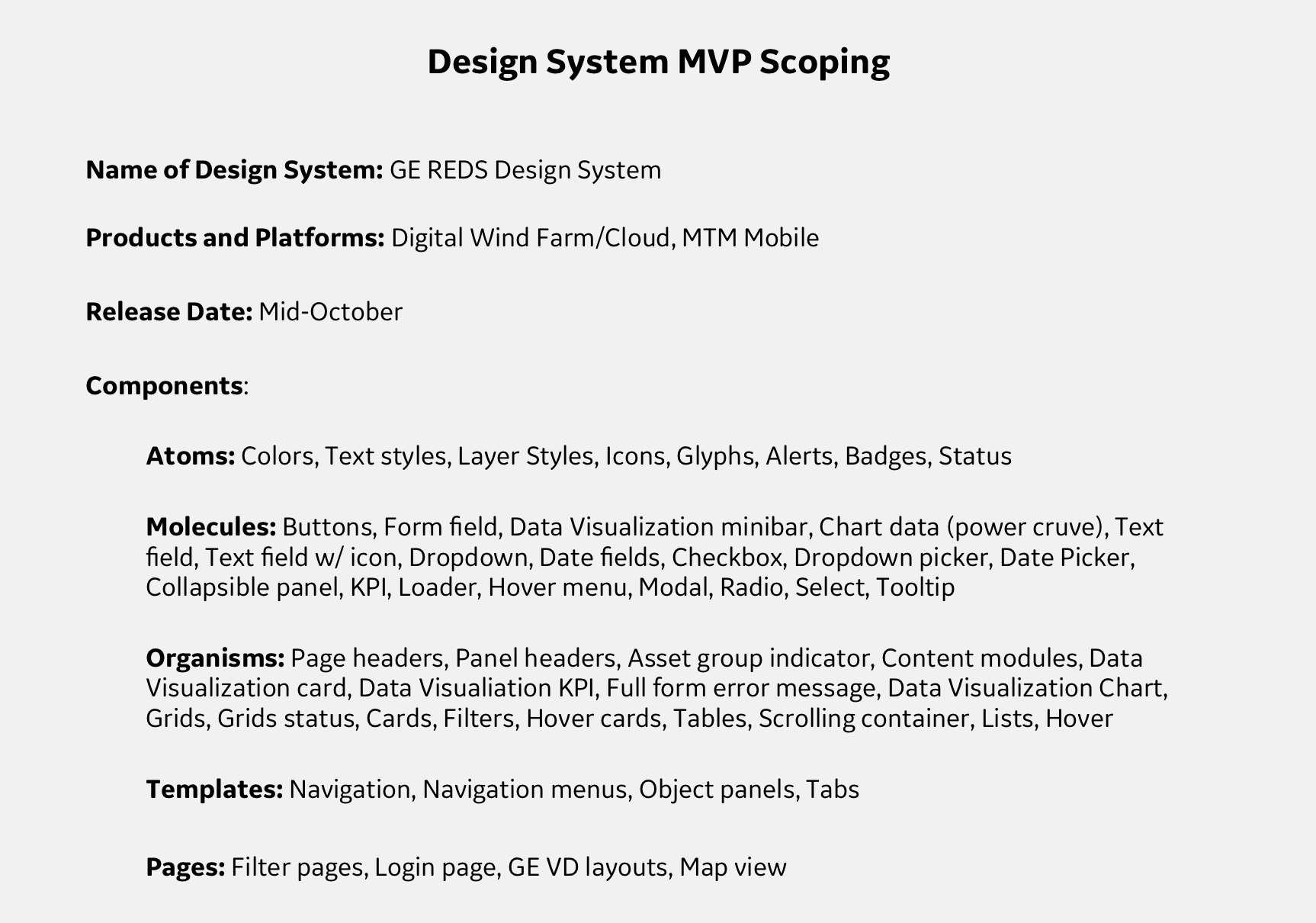

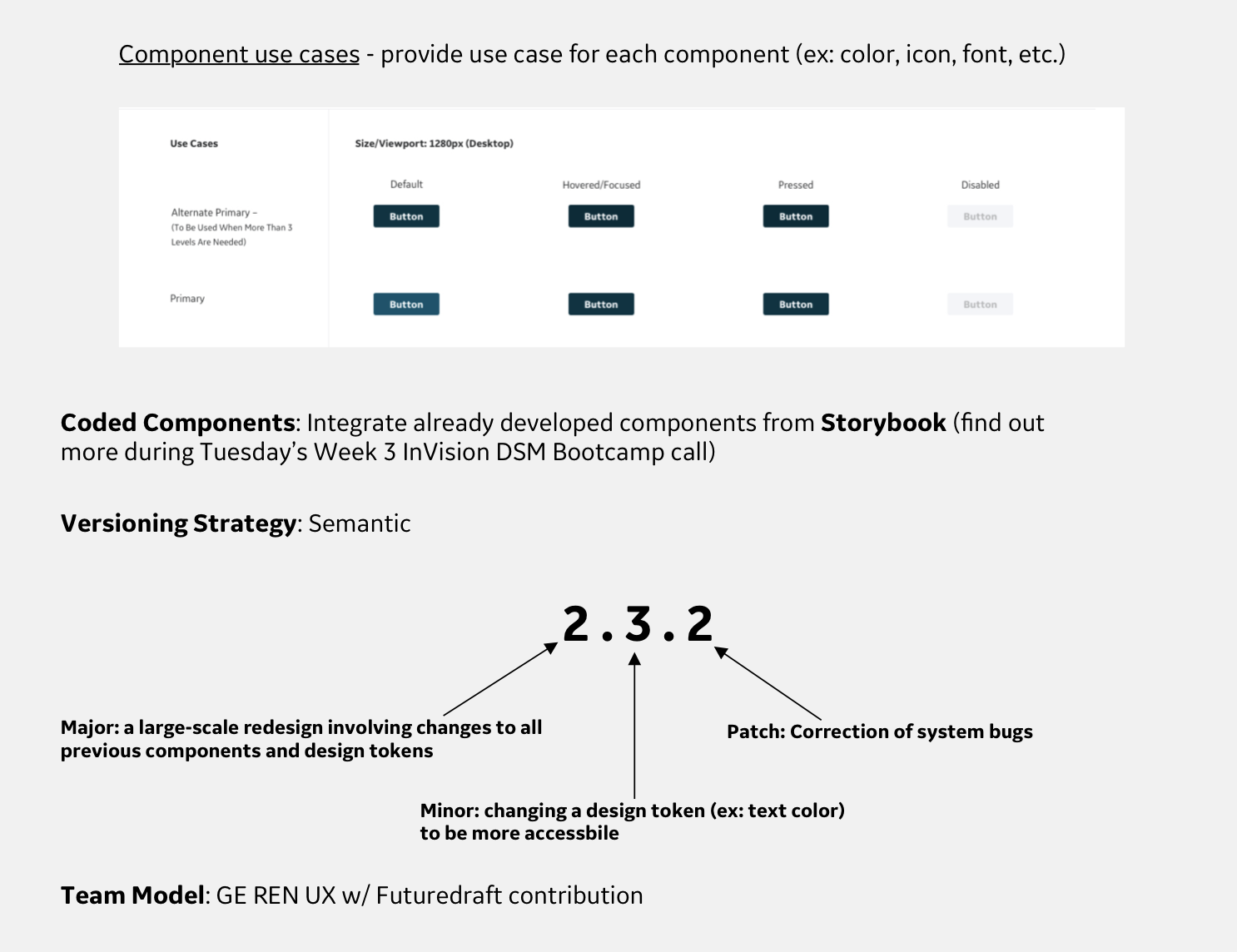

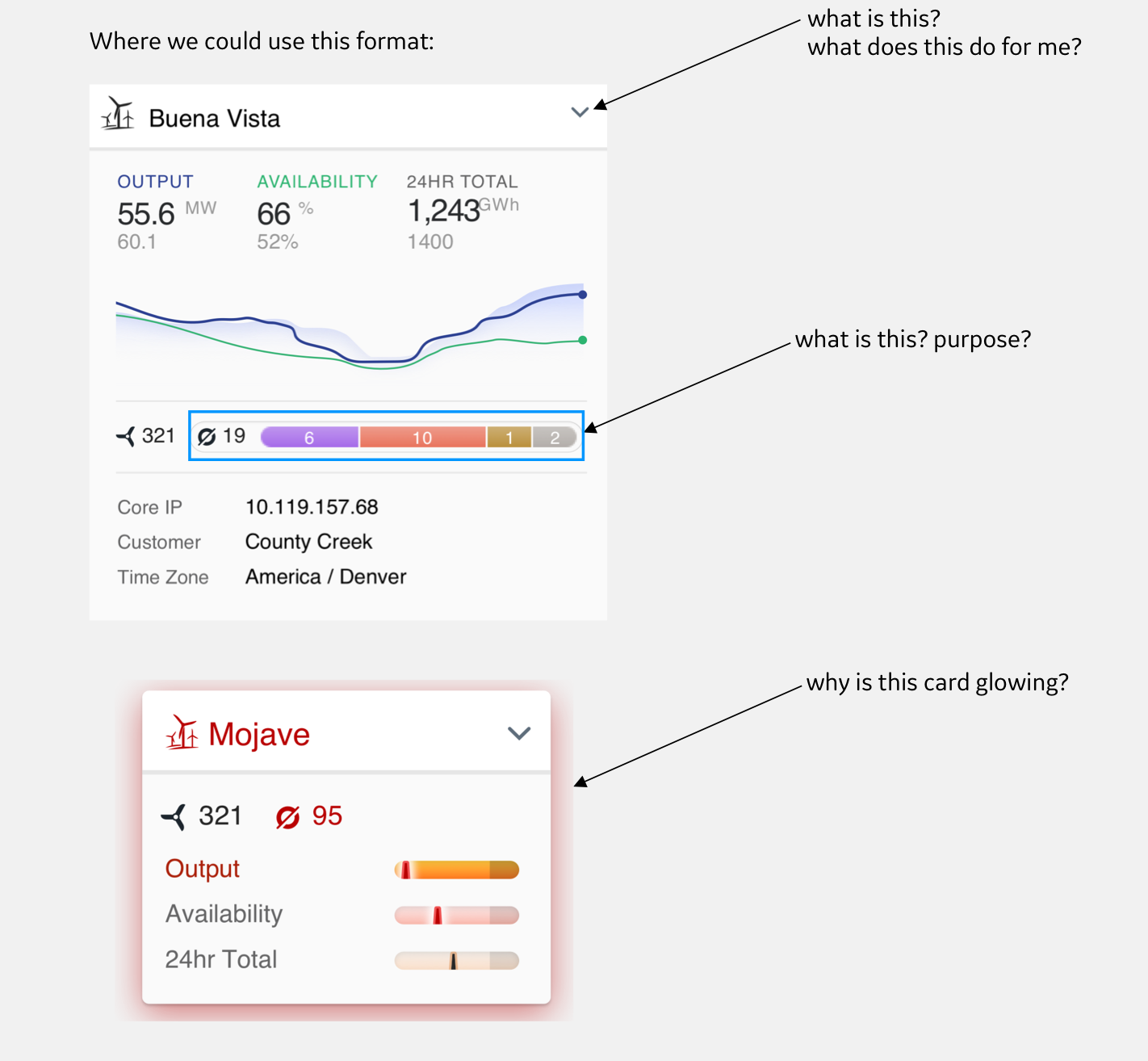

To define what the system needed, I created a scoped list of MVP components—ranging from basic atoms to full templates—and documented real examples from our current products. I also annotated existing UI components with questions like “What does this do for the user?” to spark deeper discussions with dev and product teams. This helped uncover inconsistencies, edge cases, and areas of confusion that the system could solve.

Check out a few of them below:

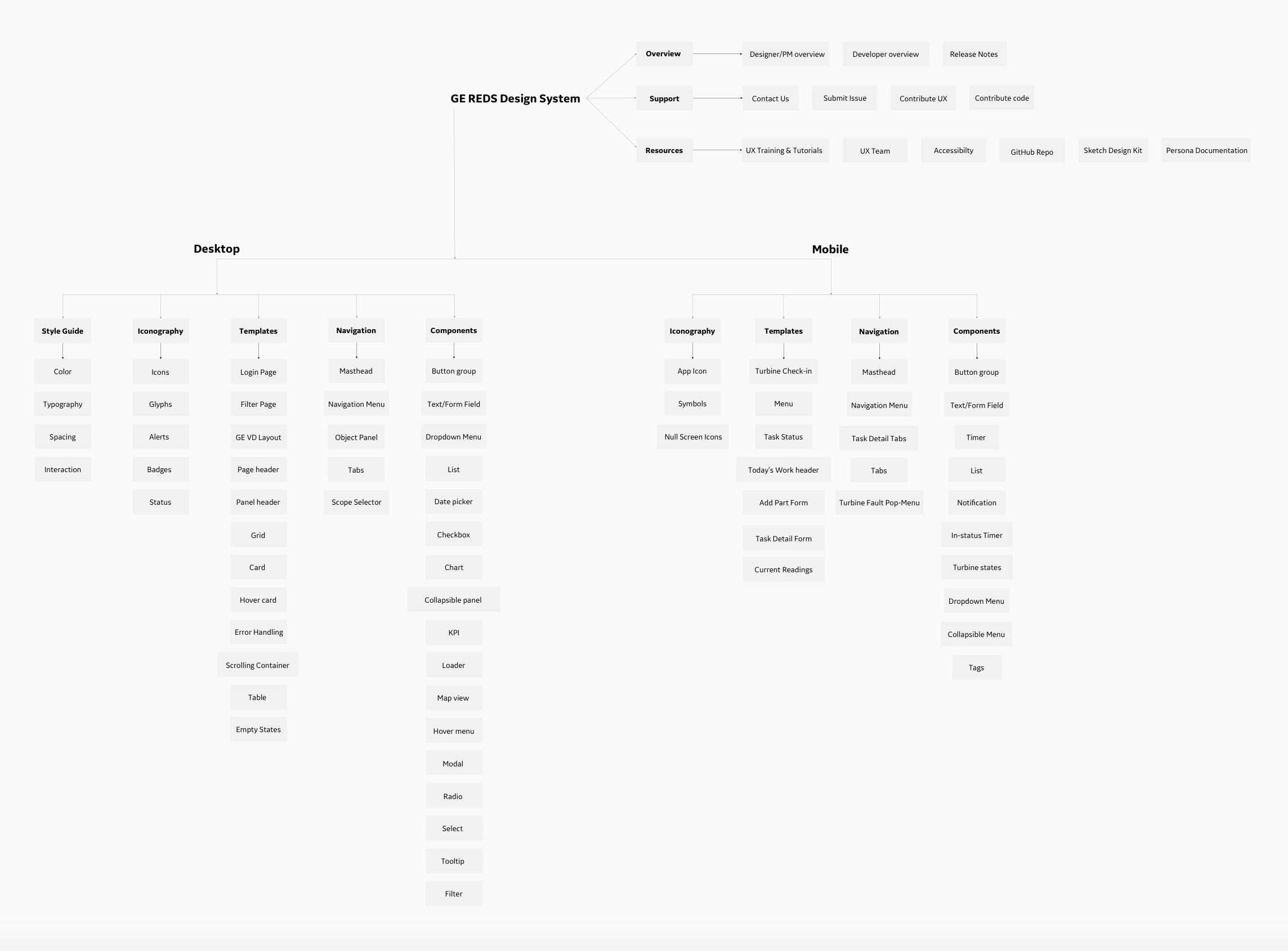

Audit & Architecture

With the foundation defined, I conducted a full UI audit across our Sketch libraries—reviewing every page, modal, menu, and interaction element.

The audit uncovered:

Dozens of inconsistent button styles

Misused font weights

One-off icons with no documentation

Redundant or contradictory naming conventions

I grouped and categorized everything, then built a scalable information architecture that supported quick access and intuitive hierarchy. I opted for grouping by usage and visual similarity—rather than atomic methodology—for clarity and ease of adoption. I apologize for the BEHEMOTH of an image below btw:

Final Solution

I’d love to share the full design system in its entirety, but due to internal privacy and security policies at GE, I’m unable to grant external access. However, I was given permission to include a few example components and documentation snapshots to illustrate the structure, organization, and visual language of the system. I want to respect the company’s wishes while still offering a glimpse into the work and rationale behind it.

The chart above reflects the rationale I used in selecting InVision DSM as our design system platform. By evaluating tool capabilities like collaboration support, Sketch integration, documentation flexibility, and learning resources, I determined that DSM offered the best balance of usability, scalability, and team alignment for our needs.

Structure & Implementation

The most time-consuming phase was cleanup and organization:

Renaming and restructuring Sketch symbols

Standardizing naming conventions

Organizing component pages with clear documentation

I used the Craft plugin to seamlessly import everything into DSM. Once imported, I tested how components behaved inside real projects and adjusted the structure to ensure developers and designers could easily find, reuse, and maintain assets.

Socialization & Adoption

After launching the initial beta version, I focused on getting buy-in and driving adoption:

Presented the system to design, product, and engineering teams

Ran feedback sessions with developers to identify friction points

Sent out weekly updates with version notes, component additions, and system improvements

I positioned the system not just as a visual tool—but as a product in itself: something that required iteration, ownership, and support.

Outcomes

Centralized all design assets into a single source of truth using InVision DSM

Reduced duplicate component count by 100%, saving design and dev redundancies

Improved handoff clarity between design and engineering

Cut design component and dev related support tickets by ~40% through standardization

Enabled scalable, consistent UI across multiple GE Renewables platforms

Takeaways

This project taught me how to lead from ambiguity—starting with no existing system, no guidelines, and no clear direction. I had to ask the right questions, explore unfamiliar tools, and do the due diligence to make informed decisions at every step. It was a hands-on lesson in systems thinking, stakeholder alignment, and scaling design across a complex enterprise environment.

What I enjoyed most was the challenge of bringing order to chaos. Seeing fragmented, inconsistent UI patterns evolve into a shared language—and watching different teams actually use that system to work faster and with more confidence—was deeply satisfying. It reminded me that good design isn't just about pixels; it's about process, communication, and enabling others to do their best work.

Building this design system wasn’t just about creating components—it was about creating clarity, trust, and alignment across disciplines. And that’s a type of impact I’m always excited to drive.